They are specialised in development, production and distribution of functional high-performance coatings for industrial applications and offer a comprehensive product portfolio covering the following areas

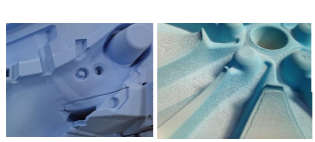

The nano-ceramic top-coating is applied thinly on the functional mould coating. The layer of some microns doesn‘t affect the base coatings roughness and properties. At 400°C the coat sinters to a very robust layer. The temperature may be reached in an oven or while casting with the melt heat. In that way a hard shell occurs to provide protection and a highly extended service time. So, coat maintenance stops are avoided, the tool provides a highly extended service. Consumption is very low, the effect is very benefitable. The coating is not compatible to all base coatings.

Product: nanocompMM12

All common coatings on the market have nanoscale ingredients. For many, the nanoparticle content is higher than that of our products. However, these ingredients cannot be made to sinter at operating temperature. This is where Nanocomp products differ from conventional coatings. Nanocomp products sinter in the process with the heat of molten aluminum at ~400°C. Ideally, the coatings are previously baked at this temperature.

LPDC/GDC Wheel Casting: nanocomp RIMTOP, nanocomp RIM7, nanocomp RimCoarse

Let us help you find exactly what you’re looking for!